fall protection systems - An Overview

A fall arrest method performs correctly only when all its components purpose collectively. Each individual element has a selected purpose to Engage in in safeguarding the employee through a fall. Here are the a few Most important factors:

Box beams are usually not usually found on new rack installs, as set up expenditures outweigh The prices discounts concerning box beams and structural beams. Also, numerous manufacturers have stopped developing box beams completely in favor of structural beams.

Employing the most House within a warehouse frequently requires getting access to a mezzanine. Having a pallet rack mezzanine, your vertical space can be employed for storage. It’s not uncommon to run away from space...

From columns & beams to wall ties & prevent bars, look into ASI's pallet racking component glossary to brush up on your own racking vocabulary!

Give consideration on the cantilever racks base height and review the quantity of storage amounts you can obtain reviewing the next:

Pallet racking is any materials managing storage method that merchants components on pallets in horizontal rows on multiple degrees. Pallet racks have to have the use of a forklift truck to load and unload...

Whatever the fall distance, fall protection need to be furnished when Doing work more than perilous machines and equipment.

Apply, exercise, practice – Acquire Protected habits and get ready teams to respond to crisis situations by routinely training fall protection strategies.

Performing at top is Just about the most hazardous duties in any industry, with falls regularly ranking One of the major leads to of place of work accidents and fatalities.

Pallet rack row spacers implement a constant volume of distance concerning two rows (aka runs) of pallet rack. Row spacers Possess a flange on each stop which secures the spacer into the frame.

Toeboards could be omitted all around car fix, support, or assembly pits if the employer can display that a toeboard would reduce access to a car which is in excess of the pit.

This selection includes a completely welded, one-assembly style and design. It offers a straightforward-to-set up choice to bolted possibilities. Geared up with common piston locks and endplates, this assembly rapidly locks into place with no need for additional components. Reconfiguring is as simple as disengaging the piston locks and fall protection systems relocating the pallet stop.

You could find it handy to realize that cantilever racking systems are available to support Particularly stressful hundreds, for example These prevalent inside the steel sector. In such super-major obligation styles, the columns are created from high energy metal, then tapered to compensate for column deflection, and pre-punched on either side for conversion from single to double-sided rack models.

Choosing the ideal racking technique is vital for optimizing your warehouse’s performance and maximizing space for storing. Regardless of whether it’s selective pallet racking, double-deep racking, drive-in racking, or pallet stream racking, Every procedure delivers distinctive Added benefits developed to specific operational desires. By contemplating things like solution types, stock turnover, and warehouse layout, you may make certain that your racking program supports present and long run needs.

Alicia Silverstone Then & Now!

Alicia Silverstone Then & Now! Joseph Mazzello Then & Now!

Joseph Mazzello Then & Now! Christina Ricci Then & Now!

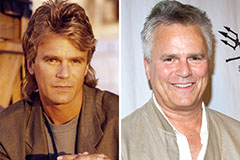

Christina Ricci Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now!